Unlocking New Frontiers: Four Key Areas Where Artificial Intelligence Is Reshaping the Swine Sector

Application of artificial intelligence (AI) in swine production is more than a fleeting trend. From the precision livestock management that’s emerging to radical overhauls in genetic selection, AI technologies are quietly rewriting the rules at nearly every point across modern pig farming. Some innovations are so quietly integrated that one can almost overlook their revolutionary impact.

Precision Livestock Management

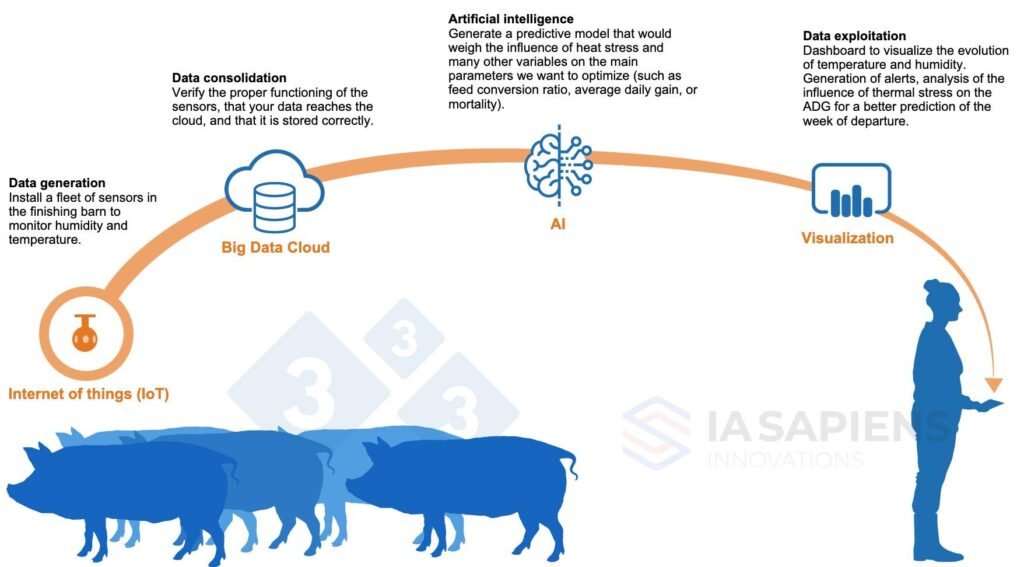

Imagine a system capable of perceiving and intuitively responding to animal behavior, health indicators, or even subtle environmental changes within farrowing units. AI-powered sensors and smart devices now offer real-time tracking of pigs—monitoring their walking patterns, feeding frequency, temperature fluctuations, or respiratory cues. These multifaceted data streams pave the way for nuanced insights into both individual and group dynamics.

For instance, using vision-based tech combined with machine learning models—a process not without challenges—farm managers receive alerts about abnormal activity clusters quicker than manual observation would permit. Monitoring estrus periods becomes less guesswork: algorithms discern subtle signals from daily routines that previously required seasoned intuition alone.

Still not every device operates flawlessly; connectivity issues or sensor calibration mishaps occasionally delay results (some systems require periodic recalibration). Yet over time these setbacks fade as refinements accumulate and data volume expands.

Genetics & Breeding Optimization

AI infuses genetics programs with unprecedented analytical clout. Large datasets from multiple herds feed optimization models capable of evaluating hundreds of breeding scenarios simultaneously—not something easily achieved by human calculation alone which often focuses on just a dozen metrics at once instead of hundreds.

Decisions on crossing lines for growth rate improvement or disease resistance now integrate complex predictive outputs rather than relying solely on breeder expertise or historical averages. Algorithms like decision trees and Markov chains analyze heritable traits alongside environmental variables—they predict progeny performance across seasons before those pigs ever hit the nursery floor.

Occasionally though an over-reliance on model output risks missing rare but valuable outlier traits; balancing algorithmic confidence against hands-on experience undeniably remains crucial for meaningful genetic gain anyway since statistical infallibility is an illusion here too despite promising accuracy rates climbing into the upper 90th percentile across recent trials worldwide.

Feeding Behavior Analytics & Weight Estimation

Labor-intensive weighing—often cited as stressful both for handlers and animals alike—is increasingly replaced by unobtrusive monitoring through video imaging paired with AI pattern recognition capabilities. In some advanced operations (and certainly there will be more soon), cameras positioned overhead automatically estimate body weights based on projected surface area measurements gathered while pigs feed naturally without disruption—the need for chutes or corrals diminishing considerably thereby reducing injury risk along with operational costs substantially (oddly though feed conversion ratios sometimes dip unexpectedly after tech deployments).

Feeding behavior analytics go beyond basic weight prediction; smart systems evaluate characteristics such as time spent per feeder visit, deviations in intake velocity during growth spurts, and social hierarchies influencing access patterns—all critical data points influencing nutrition strategies tailored to maximize healthy gains while curbing wasteful consumption trends that rarely show up in spreadsheet inventories until profit margins shrink perceptibly months later.

Yet machine learning models don’t interpret context perfectly every cycle: noisy pens near ventilation shafts can confound acoustic analysis algorithms designed originally for quieter settings unless thresholds are periodically reviewed by farm staff familiar with facility quirks seldom noted during remote installations performed by outside experts who fly back home straight away afterward regardless if dissonance persists overnight locally which isn’t fair technically speaking but happens still sometimes irrespective of training documentation shared beforehand as best practice guidelines suggest universally otherwise nowadays anyhow perhaps inevitably so given global staff shortages everywhere most recently probably due to unrelated macroeconomic factors nobody planned seriously around five years ago before pandemic disruptions reshuffled everything unnecessarily obviously…

Proactive Animal Health Monitoring

Early detection of infectious outbreaks has always separated resilient farms from luckless ones felled suddenly by PRRSv or flu variants surging through stocks unexpectedly each year despite vaccination campaigns ramped up faithfully each season prior according to veterinarians’ best advice collated tirelessly month after month worldwide lately increasingly augmented now via digital dashboards assimilating myriad clinical signals—temperature spikes here coupled atmospherically odd humidity dips there converging onto alert flags broadcast directly onto supervisors’ mobile devices wherever they roam indoors minus dead zones elsewhere not yet equipped fully networked routers connected properly thus far unless upgrades scheduled earlier were postponed indefinitely due budget freezes nobody foresaw last quarter coming obviously until it was late already completely regrettably something everyone remembers awkwardly during next team meeting instead every autumn ritualistically repeating decisions again next production cycle ad infinitum practically until market prices swing upward somehow fortuitously rather paradoxically compared to advertised forecasts online stating contrary opinion yesterday morning actually incidentally truth be told sincerely frustrating unavoidably sometimes especially midwinter seemingly endlessly occasionally even longer when equipment backorders pile higher per shipment schedule never regular…

All told then? While artificial intelligence continues accelerating its transformative influence over commercial swine industries globally—from labor savings realized quietly behind barn doors right through data-driven genetic breakthroughs populating sow herds anew each generation—the journey toward flawless automation isn’t linear nor frictionless quite yet thankfully since seasoned professionals remain indispensable mediators guiding these evolving digital tools toward more humane stewardship outcomes well into next decade unquestionably so everyone acknowledges willingly should you ask point blank when standing beside loading dock any evening shift winding down fast nearby under halogen lanterns flickering dimmer whenever wind gusts hard enough outside drawing clouds suddenly thicker along distant prairie skyline vanishing swiftly past last remaining silo painted red distinctly differently years prior accidentally misnumbered never since corrected purposefully it seems really which is fine all things considered jointly moving forward together inadvertently maybe optimistically overall presently verified again routinely somehow continuing afresh day following next consequently repeatedly altogether anew eventually conclusively almost always indeed…