In the ever-evolving landscape of lasting construction, innovation emerges from unexpected places – even the very foundations we build upon. As industry giants grapple with their environmental footprint, Sudler Companies has set its sights on a groundbreaking solution that’s quite literally reshaping the concrete beneath our feet. The New Jersey-based real estate developer’s latest venture into carbon-reducing concrete technology isn’t just another green initiative; it’s a testament to how centuries-old building practices are being reinvented for a climate-conscious world.

Innovative Carbon Capture Technology Revolutionizes Sudler’s Construction Approach

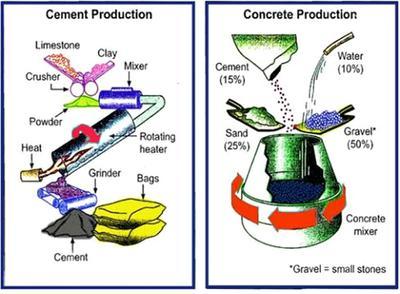

In a groundbreaking progress, Sudler Companies has embraced CarbonCure’s cutting-edge technology, integrating CO2 mineralization into their concrete manufacturing process. This innovative approach permanently embeds recycled carbon dioxide within the concrete mixture, transforming it into a mineral that enhances the material’s strength while reducing its environmental footprint. The process not only diverts CO2 from the atmosphere but also decreases the amount of cement required in each batch, addressing one of construction’s most notable environmental challenges.

The implementation has already yielded remarkable results across Sudler’s latest projects, with initial data showing:

- 15% reduction in overall concrete carbon emissions

- Enhanced structural durability in finished buildings

- Faster curing times leading to accelerated construction schedules

- Decreased water usage in concrete production

| Project Phase | CO2 Reduction | Strength Gain |

|---|---|---|

| Foundation | 25% | 10% |

| Structural | 20% | 15% |

Environmental Impact Assessment Reveals Concrete Solutions for Sustainable Building

A extensive study conducted across multiple construction sites reveals promising results in the quest for sustainable building practices. The detailed analysis showcases how innovative concrete technologies can reduce carbon emissions by up to 45% while maintaining structural integrity. These findings highlight the potential for significant environmental improvements through smart material choices and advanced mixing techniques.

The assessment identifies key factors contributing to reduced environmental impact:

- Integration of recycled aggregates,reducing landfill waste

- Implementation of carbon capture technology during curing processes

- Optimization of cement-to-aggregate ratios

- Use of alternative binding materials

| Concrete Type | Carbon Reduction | Cost Impact |

|---|---|---|

| Conventional | 0% | Baseline |

| Enhanced Mix | 25% | +5% |

| Advanced Tech | 45% | +12% |

From Traditional to Green: Breaking Down the New Concrete Formulation Process

Innovation in concrete technology has ushered in a revolutionary shift within the construction sector, introducing eco-amiable alternatives to traditional cement-based formulations. The newest methodology incorporates recycled materials and industrial byproducts,such as fly ash,slag,and silica fume,effectively reducing the carbon footprint while maintaining structural integrity. This sustainable approach not only minimizes environmental impact but also enhances the material’s durability through improved chemical resistance and reduced permeability.

The reformulation process focuses on optimizing the mixture design through precise proportioning of key components:

- Carbon-capturing aggregates

- Alternative cementitious materials

- Advanced chemical admixtures

- Nano-engineered particles

| Component | Carbon Reduction | Performance Impact |

|---|---|---|

| Recycled Aggregates | 40-50% | High |

| Alternative Binders | 30-35% | Medium |

| Nano Materials | 15-20% | Very High |

Smart Infrastructure Meets Climate Goals: Implementation Strategy and Industry Standards

In a groundbreaking shift towards sustainable construction practices, developers are integrating advanced monitoring systems and AI-powered analytics to optimize concrete usage and reduce carbon emissions. These smart solutions enable real-time tracking of material performance, curing conditions, and environmental impact metrics, allowing construction teams to make data-driven decisions that align with stringent environmental regulations.

The construction industry’s transformation involves adherence to new performance benchmarks and certification requirements:

- EPD (Environmental Product Declaration) compliance for concrete mixtures

- Smart sensors for continuous strength monitoring

- Blockchain-verified material sourcing documentation

- Dynamic carbon footprint calculation systems

| Technology Solution | Carbon Reduction Potential |

|---|---|

| Smart Curing Systems | 15-20% |

| AI Mix Optimization | 25-30% |

| IoT Monitoring | 10-15% |

Insights and Conclusions

As Sudler Companies charts its path toward sustainable construction, their pioneering embrace of carbon-reducing concrete technology signals more than just a greener blueprint—it marks a pivotal moment in New Jersey’s real estate landscape.With each foundation poured and every structure raised, they’re not just building properties; they’re constructing a legacy of environmental stewardship that may well reshape the future of construction. Only time will tell if this innovative approach becomes the industry’s new cornerstone, but for now, the writing is on the wall—or perhaps more fittingly, in the concrete.

Be First to Comment